|

Ningbo Newland International Trade Co., Ltd.

|

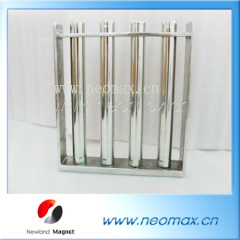

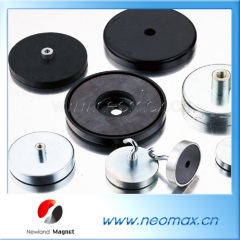

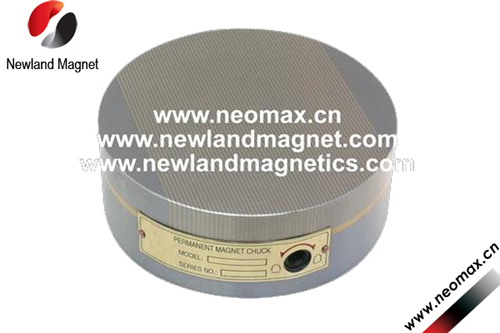

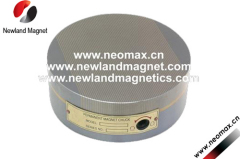

round magnetic chucks

| Price: | 1.0~100.0 USD |

| Payment Terms: | L/C T/T Western Union,money gram |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

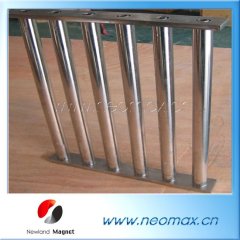

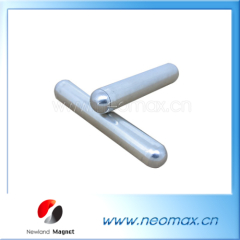

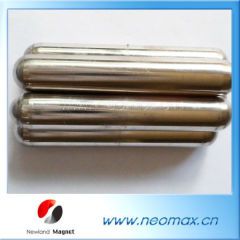

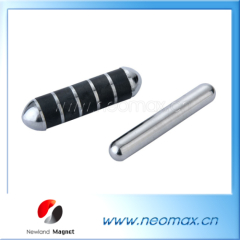

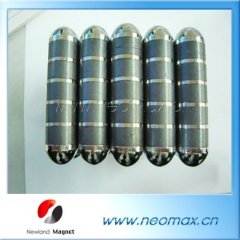

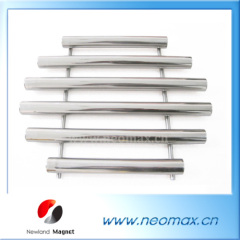

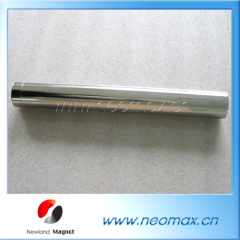

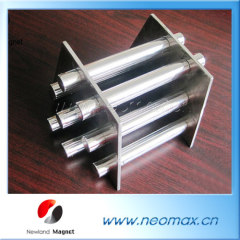

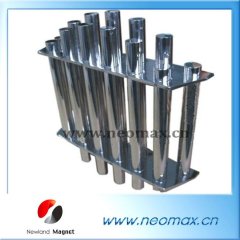

Newland Magnetics are supplying all various of the Permanent Magnetic Chuck such normal, fine-pole,

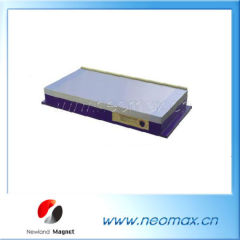

Newland Magnetics are supplying all various of the Permanent Magnetic Chuck such normal, fine pole, Double Sine Plate with fine Magnetic Chuck, super fine-pole and heavy suction super fine-pole,Single Angle Permanent Magnetic Sine Table etc. Our chucks are made of high quality Nd-Fe-B alloys and have the features of heavy suction, uniform magnetic field distribution, minimal residual magnetism and high efficiency. It is easy and safe to be used and has a long work life and suitable to be used as fixture in CNC, surface grinder, liner cutting machine and electric discharge machine etc. Positive locking at all angles without any distortion. Large effective area is provided for machining the work pieces.

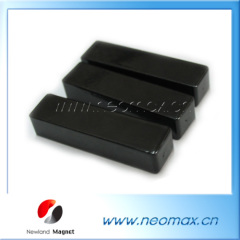

Rectangle Permanent Magnetic Chuck with extra strong magnetic force and less remaining magnetism coolant and water proof structure. Magnetic chucks are with high magnetism,

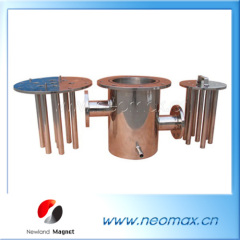

to meet your specific requirements. Circular Permanent Magnetic Chuck is used for specific

requirements in industry.

Rectangle Permanent Magnetic Chuck with extra strong magnetic force and less remaining magnetism coolant and water proof structure. Magnetic chucks are with high magnetism,

to meet your specific requirements. Circular Permanent Magnetic Chuck is used for specific

requirements in industry.

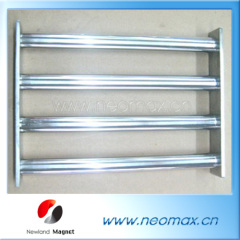

Newland Magnetics have many models of chucks: rectangle steel permanent magnetic chuck, sine plate with fine magnetic chuck, double sine plate withe fine magnetic chuck, leaning permanent magnetic chuck, circular permanent magnetic chuck, wire-cutting versatile chuck, grinding wheel dresser, magnetic V-block

Our magnetic chucks are with strong magnetism and high quality. If you have any inquiry, feel free to let us know. We are willing to offer you. Thanks for your consideration.

1. Daily Maintenance

1. Please clean the work-surface of magnetic chuck, in order to avoid rusting on the surface. If rusting, it will effect next using;

2. It is necessary to frequently check the work-surface of magnetic chuck if have spoil and scratch. Because these will effect its attractive power and work-piece's required tolerance. If, after long-term use, these spoil or scratch come out, you can grind its work-piece on itself grinding function, and keep its original plane tolerance;

3. to cover with anti-rust grease(oil) on the work-surface if no use for long time.

2. FAQ(frequency answer question):

4. chucks have no more magnetic power;

Please check whether its switch (handle) turn on completely;

5. weak magnetic power :

1). Please check if its switch (handle) turn on completely;

2). To check whether chucks can't attract other work-pieces;

3). To check its hold position: if the power on the center position is stronger than other position's. if not, please call service.

6. The work-piece can't release from the magnetic chuck:

1). To check if the handle turn off completely;

2). To check whether magnetic chuck can attract small iron nuts or not on the other position when the handle turns off completely.

Features:

Large effective area is provided for machining the work pieces.

Positive locking at all angles without any distortion.

Constructed of hardened alloy tool steel.

Angle precision 0.007/ 100mm.

Low height for more wheel clearance.

Large effective area is provided for machining the work pieces.

Positive locking at all angles without any distortion.

Constructed of hardened alloy tool steel.

Angle precision 0.007/ 100mm.

Low height for more wheel clearance.

Application:

Flat type for wide ranges of uses.

Ideal for high accuracy grinding operations.

Flat type for wide ranges of uses.

Ideal for high accuracy grinding operations.

3. Note:

In order to ensure its parallel between magnetic chuck and grinding machine, you'd better firstly grinding its surface plate after the magnetic chuck are fixed on the grinding machine .If the work-surface become rough after long time use, its magnetic power will get weak, please grinding its surface again.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)